Lithium-Ion Battery Safety Notes

Safety Precautions for Lithium-Based Batteries and Lithium-Powered Systems

Disclaimer

The purchaser of GlobTek battery pack products (Customer) agrees that they are a "Sophisticated user" who understands battery technology and that it is their sole responsibility to determine suitability of the product described for their application and to take precautions for protection against any hazards attendant to the handling and use of the product. GlobTek products are only designed for professional use and integration by companies into their products and may not be used by consumers directly. GlobTek provides batteries and battery packs as a component of an end system.

The acceptance of GlobTek specifications, the information on this page and use of the product(s) described in this or other GlobTek documents indicate that the product was qualified for use (tested and/or sample waiver signed), and the acceptance and binding of the customer to GlobTek terms and conditions, which supersede all other agreements, terms and conditions (http://en.globtek.com/terms-and-conditions/).

Introduction

The chemicals present in lithium-based batteries are more reactive than those found in other battery technologies. Broadly speaking, this means the rate of the chemical reaction, at a given set of input conditions (i.e. temperature), is greater. Without appropriate considerations, lithium chemistries can encounter scenarios which put the safety of the battery (and system) at risk.

System / End-Equipment Considerations

The following does not represent an exhaustive list; It is for reference only.

- Always include protection circuitry: A lithium battery should not be used without a battery management system (BMS) which ensures that the battery is not used outside of its safe operating area (SOA). While GlobTek is capable of manufacturing unprotected batteries, it is highly recommended to select /specify a battery pack which includes protection circuitry. The absence of protection circuitry, either in the battery or in the end-system, is extremely risky and increases the likelihood of fire, and/or injury/death. Protections include, but are not limited to:

- Over-current (during charge & discharge)

- Over-discharge (under-voltage)

- Over-charge (over-voltage)

- Over-temperature

- Cell unbalance (multi-cell series packs only)

- Prevent prolonged high state-of-charge (SoC): GlobTek's standard battery packs are designed for a "typical" use case in which the battery is regularly charged and discharged. Extended periods at a high state of charge may lead to premature failure due to lithium plating. Applications with infrequent discharge should consider the following. (More information under 'Charging').

- Use a lower charge voltage, equivalent to 70% SoC or lower, for operation down to 10°C [1]

- Use intelligent circuitry to regularly force a discharge cycle below 40% SoC [1]

- Use an alternate battery chemistry

- Consider enclosure flammability: The flammability rating of the end-system's enclosure is important to the overall safety of the system. Proper battery management will protect packs against the vast majority of destructive failure modes. However, low-occurrence cell defects and unforeseen usage can still compromise a system's safety. Thus, to ensure a pack failure does not endanger human life, the housing design and material should be aptly selected. (See UL94-5.)

- For systems with user-accessible/removable batteries, the pack may be enclosed in a fire-rated, injection-molded plastic housing. The self-extinguishing properties of this plastic may add an additional layer of safety to the system, though it still important to allow proper venting and spacing within the housing. This plastic housing also serves to prevent mishandling/disassembly of the pack by the end-user.

- For systems with non-accessible batteries, the pack is typically enclosed in shrink-wrap plastic. In this case, the shrink-wrap typically cannot be relied upon for any level of fire protection.

- Keep away from heat sources: The battery pack should be positioned far away from heat generating components within a system or within a charger unit. Thermal runaway of fresh lithium cells typically occurs between 130 - 170°C. [2] While far away from the typical 60°C operating temperature rating, a combination of high discharge rate (large internal heating), high SoC, proximity to heat source(s), and/or aging cells may lead to an unexpected thermal runaway event.

- Prevent drops and sudden impacts: Use a sturdy locking mechanism to prevent the battery pack from being ejected when the equipment is dropped or receives a sudden impact.

- Prevent external short circuits and reverse polarity: Use a terminal structure which makes it unlikely that the terminals will be shorted by foreign metallic objects, such as necklaces, paper-clips, hairpins, etc. Use a "keying" mechanism (integrated into the housing and/or a keyed connector) to prevent battery packs from being installed in reverse. Check if the selected battery pack has integrated reverse polarity protection. If not, consider adding a reverse polarity protection circuit.

- Allow for ample space and venting within the battery compartment: A failing cell often generates excess gas within the cell casing. These gasses must be vented in order to lower the cell's internal pressure and temperature. A perfectly sealed battery compartment will trap the expelled gasses and will prevent proper relief of the pressurized system. In a thermal runaway failure, cylindrical lithium-ion cells may also vent hot projectiles from the top or bottom of the cell. [3] To lower the risk of propagating thermal runaway to other cells, provide sufficient clearance between the cells' tops/ bottoms and the system housing or other components. [4] Lithium-polymer pouch cells typically expand by around 10%, on the Z-axis, over their useful lives. Therefore, the battery compartment should allow at least 10-15% (minimum) extra height to account for this phenomenon. Pouch cell expansion by ~10% is normal and expected.

- Use appropriate mating connector materials: The contact material of the mating connector should match the material of the battery's contacts to avoid issues related to fretting and galvanic corrosion. For outdoor use, or in other harsh environments, specify corrosion resistant contact materials such as gold, gold-cobalt, or gold-nickel. [5]

To ensure safe system implementation, be sure to consult with GlobTek regarding pack specifications and for additional input on your specific system.

Charging

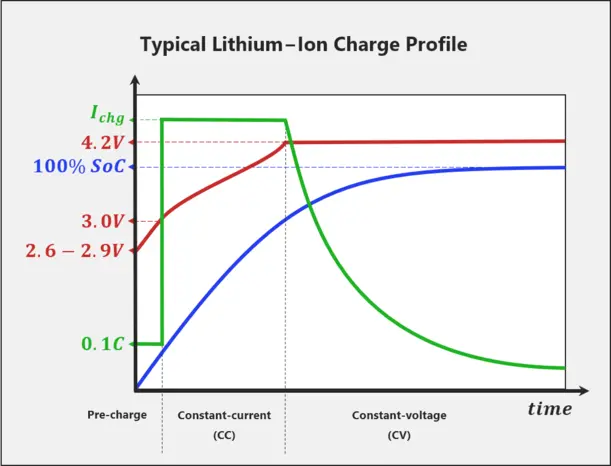

A multi-stage charger with a constant-current/constant-voltage (CC/CV) profile is the most popular way to charge lithium batteries. CC/CV allows for fast charging while preserving battery health by limiting the current (in CC mode) and preventing over-charge (in CV mode). The CC/CV charging method helps to avoid undesirable electro-chemical phenomena within the cells. The two main charge parameters are current in CC mode, and set-point voltage in CV mode. These parameters can be adjusted to balance cell capacity, charge time, and the number of expected charge/discharge cycles.

The following information refers to packs using lithium cells with manufacturer-stated 4.20V maximum charge voltage. Make appropriate adjustments for different chemistries and cell voltages. For packs without integrated chargers, the following information serves as starting-point guidance into a proper design.

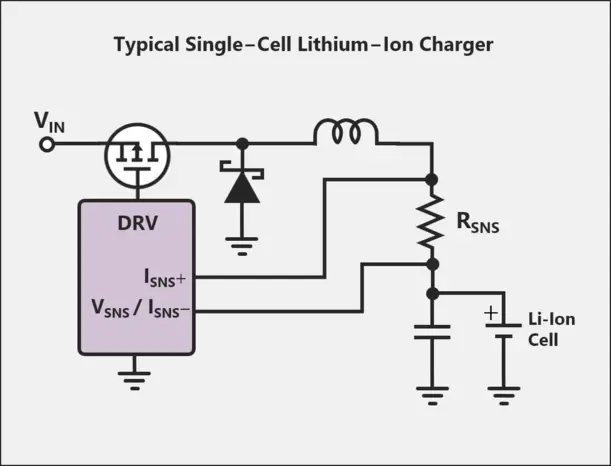

The figure below shows a simplified single-cell buck lithium ion charger circuit. Note its ability to sense the voltage across the cell and the current through it.

The figure below shows a typical charging profile of a depleted lithium-ion cell. Note: Some chargers/packs may choose to terminate the charge current in CV mode once a certain current threshold is reached (0.05C, for instance). Charging resumes once the cell voltage dips beneath some set-point. Other chargers may maintain the full charge voltage continuously via trickle charging.

Charge Voltage

Charge Voltage

The maximum voltage is 4.20V (±0.05) x (# of cells in series). Charging to the maximum voltage (4.20V) allows for greater energy storage at the expense of reduced charge/discharge cycles. It is important to consider the tolerance of the charger's output voltage as exceeding the maximum voltage by a small amount can impact the life and health of the cell(s). GlobTek recommends a charge voltage of 4.10V for most applications.

In general, maintaining an SoC above ~70% for prolonged periods increases the likelihood of lithium plating on the anode. [1] Lithium plating is detrimental to cell capacity and may lead to internal short-circuit(s) in severe cases. For backup or standby applications, the maximum recommended charge voltage is 3.95V, which equates to approximately 70% SoC for typical lithium-ion cells. If greater cell-voltage or capacity is required for standby applications, the battery should be regularly discharged below 40% SoC to strip the lithium from the anode, reversing many of the adverse effects. Failure to discharge regularly will cause irreversible damage to the cells.

Charge Current

The maximum charge rate for most cylindrical (lithium-ion) and pouch (lithium-polymer) cells is 0.5C. GlobTek recommends 0.2C for some cells. Some cells may allow up to 1.0C. Please check the respective specification of the battery pack in question. Similarly to charge voltage, the charge current can also have an effect on the expected life and available capacity of the battery pack. In addition, a higher charge current causes more internal heating, so it is important to consider the ambient temperature during charging.

For a deeply discharged cell with a voltage of 3.0V or less, a pre-charge current equal to or less than 0.1C is highly recommended.

Contact GlobTek for information regarding pulse charging.

Charge Temperature

Battery packs should be charged at temperatures between +10°C and +45°C.

Discharging

Discharge Current

The steady-state current should not exceed 1.0C. Contact GlobTek for applications requiring discharge rates greater than 1.0C.

Discharge Temperature

Battery packs should be discharged at a temperature between -10°C and +60°C. Contact GlobTek for applications outside of this range.

Discharge Termination Voltage

Lithium based batteries should avoid discharge below 3.0V. Even if discharge is terminated at 3.0V, self-discharge may cause the cell voltage to drop further. GlobTek recommends a permanent fail protection if the cell voltage drops to 2.50V. Over-discharge may affect the performance and safety of the battery. Equip the unit with a mechanism to prevent over-discharge, especially in situations where the user may forget to turn the equipment off.

Storage

Battery packs should be stored at room temperature (20°C nominal), and charged to an SoC between 30 and 50%. Humidity is often overlooked, but is of equal importance. Make sure humidity is maintained at 50% or less. Check if your storage facility can meet these requirements, and if not, consider allocating space for a separate climate-controlled lithium battery storage unit.

Maintenance charging is suggested at 3 month intervals for ambient temperatures between -20 and 25°C. Maintenance charging is suggested at 1 month intervals for ambient temperatures between -20 and 60°C. Self-discharge increases with increasing temperature. It is important to prevent battery packs from over-discharge while in storage. For each maintenance cycle, the batteries should be restored to an SoC between 30 and 50%, just as with the initial pre-storage charge.

Batteries which experienced shock or extreme vibration (such as being dropped on the floor)

ANY BATTERY OR BATTERY PACK WHICH HAS BEEN DROPPED OR EXPERIENCED SHOCK OR VIBRATION MUST BE TAKEN OUT OF SERVICE IMMEDIATELY.

Lithium based batteries and cells may get damaged from shock or vibration, which could be as simple as a result of being dropped on the ground. Such vibration and shock could cause damage to the internal construction of the battery cell(s), cause unwanted chemical reactions such as, but not limited to dendritic growth, and/or associated safety electronics within a battery pack which could lead to catastrophic failure such as fire and cause risk to life and property. It is also suggested to inspect and confirm there is no mechanical damage to batteries before each use. It is both very costly and also very challenging to determine if internal damage has occurred in a dropped or damaged battery and typically most economical to simply take such batteries out of service.

It is strongly suggested all users of GlobTek batteries to include in their user manual, service manual, or other technical or service literature clear instructions and warnings that any battery which experienced ANY sort of shock or vibration which was not intended by the OEM (GlobTek's customer) must be removed from service immediately and safely and legally discarded. It is also suggested removable battery packs, such as the type used in power tools, be considered in a system level package which would prevent them from not being secured and protected in transportation (i.e. a carrying case including a safe location for a battery could prevent the battery from "bouncing around" a users tool box or repair truck).

Life Expectancy

As noted above, the performance and life expectancy of batteries depends heavily on the usage of the pack.

Rechargeable batteries work by running a series of chemical reactions "forward" (to discharge) and "in reverse" (to charge). Due to the chemical nature of a battery, the number of times these reactions may occur is limited. The chemical structure is influenced by it's usage (charge/discharge) and various environmental conditions. If a battery pack is used outside of its specified ratings, the life expectancy of the battery may be shortened and/or the device in which the battery is used in may be damaged. If a battery pack cannot maintain a charge, even after a proper charge cycle, it may be time to replace the battery. An end-system may request parameters related to a battery health using I2C/SMBUS, for applicable battery packs.

Battery life may be prolonged by operating the battery pack in a mid state of charge, between 30 and 80%. Avoid ultra-fast charging and heavy load conditions.

Trade/Import/Export

When exporting batteries, they are likely to undergo the judgment on classification of strategic products according to the Export Trade Control Ordinance. Please contact GlobTek for additional information.

References

[1] A. H. Z. a. M. V. Quinzio, "Lithium Plating in Lithium-Ion Cells," 2010. [Online]. Available: https://www.nasa.gov/sites/default/files/atoms/files/1-lithium_plating_azimmerman.pdf.

[2] A. W. Golubkov, D. Fuchs, J. Wagner, H. Wiltsche, C. Stangl, G. Fauler, A. Thaler and V. Hacker, "Thermal-runaway experiments on consumer Li-ion batteries with metal-oxide and olivin-type cathodes," RSC Adv., vol. 4, 2014

[3] D. P. Finegan, E. Darcy, M. Keyser, B. Tjaden, T. M. M. Heean and R. Jervis, "Identifying the Cause of Rupture of Li‐Ion Batteries during Thermal Runaway," Advanced Science, vol. 5, no. 1, 2017

[4] US Federal Aviation Administration, "Summary of FAA Studies Related to the Hazards Produced by Lithium Cells in Thermal Runaway in Aircraft Cargo Compartments," 2016.

[5] J. Song, L. Wang, A. Zibart and C. Koch, "Corrosion Protection of Electrically Conductive Surfaces," Metals, vol. 2, 2012.

GlobTek assumes no liability for problems that occur when the notes and precautions for use listed above are not followed.

When Using the Battery

DANGER

- Misusing the battery may cause the battery to get hot, explode, or ignite and cause serious injury. Be sure to follow the safety rules listed below:

- Do not place the battery in fire or heat the battery.

- Do not install the battery backwards so that the polarity is reversed.

- Do not connect the positive terminal and the negative terminal of the battery to each other with any metal object (such as wire).

- Do not carry or store the batteries together with necklaces, hairpins, or other metal objects.

- Do not penetrate the battery with nails, strike the battery with a hammer, step on the battery, or otherwise subject it to h3 impacts or shocks.

- Do not solder directly onto the battery.

- Do not expose the battery to water or salt water, or allow the battery to get wet.

- Do not disassemble or modify the battery. The battery contains safety and protection devices which, if damaged, may cause the battery to generate heat, explode or ignite.

- Do not place the battery on or near fires, stoves, or other high-temperature locations. Do not place the battery in direct sunshine, or use or store the battery inside cars in hot weather. Doing so may cause the battery to generate heat, explode, or ignite. Using the battery in this manner may also result in a loss of performance and a shortened life expectancy.

- Do not insert the battery into equipment designed to be hermetically sealed. In some cases hydrogen or oxygen may be discharged from the cell which may result in rupture, fire or explosion.

WARNING

- Immediately discontinue use of the battery if, while using, charging, or storing the battery, the battery emits an unusual smell, feels hot, changes color, changes shape, or appears abnormal in any other way. Contact your sales location or GlobTek if any of these problems are observed.

- Do not place the batteries in microwave ovens, high-pressure containers, or on induction cookware.

- In the event that the battery leaks and the fluid gets into one's eye, do not rub the eye. Rinse well with water and immediately seek medical care. If left untreated the battery fluid could cause damage to the eye.

CAUTION

- If the device is to be used by small children, the caregiver should explain the contents of the user's manual to the children. The caregiver should provide adequate supervision to insure that the device is being used as explained in the user's manual.

- When the battery is worn out, insulate the terminals with adhesive tape or similar materials before disposal.

DANGER

Be sure to follow the rules listed below while charging the battery. Failure to do so may cause the battery to become hot, explode, or ignite and cause serious injury.

- When charging the battery, either use a specified battery charger or otherwise insure that the battery charging conditions specified by GlobTek are met.

- Do not attach the batteries to a power supply plug or directly to a car's cigarette lighter.

- Do not place the batteries in or near fire, or into direct sunlight. When the battery becomes hot, the built-in safety equipment is activated, preventing the battery from charging further, and heating the battery can destroy the safety equipment and can cause additional heating, breaking, or ignition of the battery.

WARNING

Do not continue charging the battery if it does not recharge within the specified charging time. Doing so may cause the battery to become hot, explode, or ignite.

While Charging

CAUTION

The temperature range over which the battery can be charged is 10°C to 45°C. Charging the battery at temperatures outside of this range may cause the battery to become hot or to break. Charging the battery outside of this temperature range may also harm the performance of the battery or reduce the battery's life expectancy.

When Discharging the Battery

DANGER

Do not discharge the battery using any device except for the specified device. When the battery is used in devices aside from the specified device it may damage the performance of the battery or reduce its life expectancy, and if the device causes an abnormal current to flow, it may cause the battery to become hot, explode, or ignite and cause serious injury.

CAUTION

The temperature range over which the battery can be discharged is -10°C to 60°C. Use of the battery outside of this temperature range may damage the performance of the battery or may reduce its life expectancy.

To ensure the safe use of this battery, contact GlobTek when designing a device that uses this battery.The acceptance of GlobTek specifications and use of the product described in the website and specification or marketing documents indicates the acceptance and binding of the customer to GlobTek terms and conditions, which supersede all other agreements, terms, and conditions https://en.globtek.com/terms-and-conditions/

FIRE HAZARD

Lithium Ion batteries are inherently dangerous. Continuous usage or charging without allowing the battery to discharge is a hazard. The purchaser of battery product (Customer) agrees that it is their sole responsibility to determine suitability of the product described for their application and to take precautions for protection against any hazards attendant to the handling and use of the product as well as the responsibility for safety and prevention of catastrophic failure of any battery used with this charger. GlobTek Battery packs or battery charger products may not be relied on as the sole protection mechanism in the system in which it's used without the review and written agreement by a Principle of GlobTek.